CUSTOM CABINET FINISH

When it comes to selecting a custom cabinet finish, you want to focus on both appearance and durability. You want a color that looks good and works well with the surrounding decor. And since you are actively using the cabinetry, you want a finish that can handle the daily activity.

Ultimately, most people will choose either a paint or stain to get the color they desire. The other option is to leave the natural wood.

Paint will cover the wood, whereas stain will darken and bring out the grain pattern. Whether you choose to color or to leave the natural wood, there needs to be a finish coat.

Ladies who have their nails manicured can appreciate the value of a top coat. It protects and seals the color underneath and lengthens the time between salon visits.

THE TOP COAT (Sealer)

There are multiple materials that can be used to seal wood cabinets, but only two really matter. Those are Lacquer and Varnish, specifically Conversion Varnish. Others, such as Shellac, which can’t compete in durability, or Polyurethane, which takes too long to dry, won’t be discussed here.

- Lacquer and Varnish can be purchased at a hardware or home improvement store.

- Lacquer is best applied with a sprayer, whereas Varnish can be applied with a brush.

- Conversion Varnish is usually only found through specialized distributors or directly from manufacturers and needs to be applied with a sprayer.

- As compared to store bought varnish, Conversion Varnish differs in that it has an added accelerant to speed up drying time.

CONVERSION VARNISH vs LACQUER

For the best custom cabinet finish, our choice is Conversion Varnish (CV) over Lacquer, and here’s why…

- The CV topcoat is extremely durable and easy to clean. It is resistant to heat, water, wear, solvents, acids, and alkalis.

- The high solids content (40%-60%) means it requires less coats to build a quality film.

- CV is low in volatile organic compounds (solvents), which makes it environmentally friendly.

- It contains self sealers and has excellent non-yellowing properties.

- The product is sprayed on, dries hard and quickly, and results in a very attractive clear coat.

- CV is used by top end furniture makers, including the Amish craftsmen.

- The only disadvantage is that you would not want to try this at home. For proper bonding and dust control, this is a process best left to skilled professionals!

Now, let’s compare to a Lacquer finish. When properly applied, Lacquer will – and should – be indistinguishable from a CV finish. However, the differences will ultimately become apparent.

- Lacquer contains 12%-18% solids, much less than that of CV. In other words, it has rather poor film building characteristics.

- It has high volatile organic compound content, which is harmful to the environment.

- Lacquer is less resistance to heat, scratches, solvents, acids, and alkalis than a CV finish.

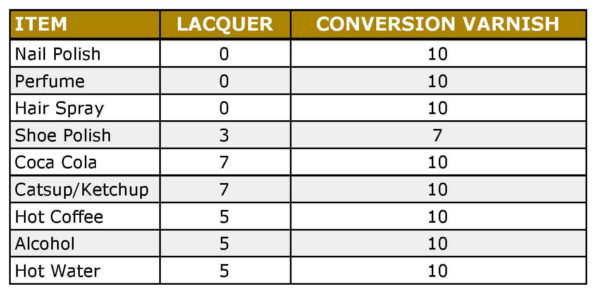

The chart below shows test results for chemical resistance of each finish. Using 0-10 scale, where 0=Severe effects and 10=No effect. That means 0 is not good and 10 is the best you can get.

We hope this information has been helpful to you.

We hope this information has been helpful to you.

C&L Design Specialists provides knowledge about custom cabinetry as part of our commitment to our clients.

As always, we will continue to use only the finest finishes available, and that’s why our motto is Expect Excellence!!!